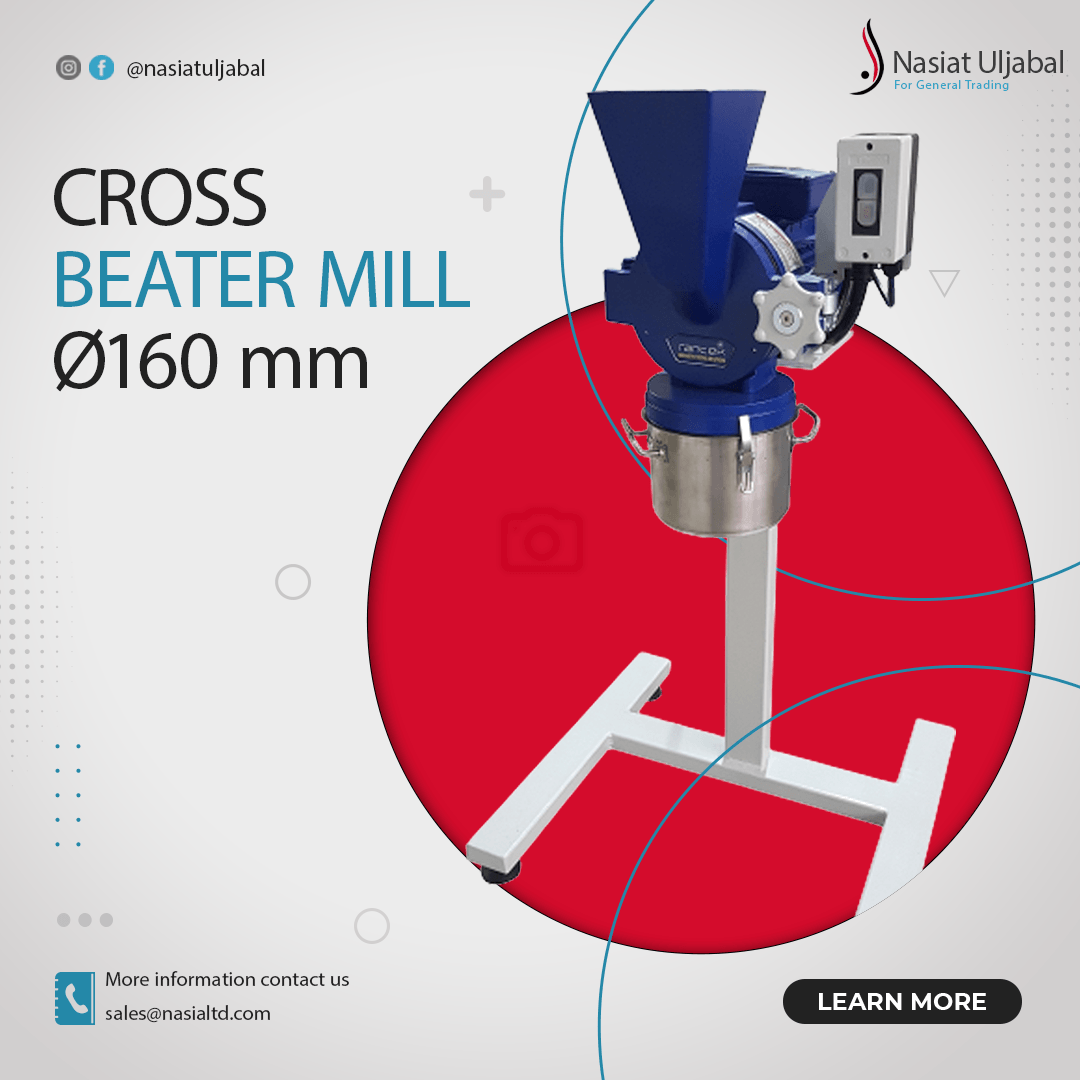

CROSS-ROTOR GRINDER Ø160 mmThe cross-rotor grinder is the appropriate device for reducing the size of continuous or partial rough samples.

It is suitable for working with brittle, medium-hard materials.

RAM170 is suitable for general use in pilot plant or laboratory scale sample preparation.

Application Examples

Cement, clinker, Glass, Coke, Coal, Ceramic Powder, Pebble, Gypsum, Slag, Ore, Granite, Minerals, Ceramics, Soil, Dried Foods, Solid Waste Fuels ...

Product AdvantagesSuitable

for large, bulk samples Output fineness of desired size thanks to sieves used between 0.15 and 10 mm

Rotors and screens Easy to clean and replace, rotors and screens Wide range accessories including different collection and feeding systems, rotors and screens

Optional cyclone is available.

Technical SpecificationsGrinder Rotor Inner Diameter : Ø160 mm Applications : size reduction Feed material : medium-hard, brittle

Size reduction

principle : effect

Material inlet size < 25 mm

Output size < 150 μm

Speed, 3000 rpm

at 50 Hz (60 Hz) Rotor type : Stainless Steel / High Strength Heat Treated Steel

Material of grinder elements : hardened steel, stainless steel

Screen size

•• Trapezoidal holes 0.15 / 0.20 / 0.25 / 0.35 / 0.50 / 0.75 / 1.00 / 1.50 / 2.00 mm •• Round holes 3.00 / 4.00 / 5.00 / 6.00 / 8.00 / 10.00 mm

Dust drawing unit : optional cyclone

Collector capacity : 5 Lt

Motor power : 1.1 kW

Electrical : 220 - 240 V, 50/60 Hz or 380 V, 50 Hz

Protection code : IP 41

Approximate Weight ~ 60 kg (with base frame)

Standards : CE

2023-01-17 02:58 PM 1038